Unwind Stands

More Info

A Double E unwind stand is a rugged, complete, packaged solution for unwinding web material. It features the highest quality accessories available, appropriately specified for your application, and pre-configured for easy integration into your process.

If you would like more information, or if you would like to receive a quotation for your specific application, please click here.

Solution Series Roll Stands

Entire system is designed specifically for your application by Double E's expert engineers.

Pre-assembled roll stand has a warranty as a package from one supplier. All components work together for optimal winding control without the hassle of installing each accessory.

Flexible design allows low costs for stands ranging from simple stationary unwind stands to more complex motorized rewind stands. Prices for new equipment from Double E are often lower than comparable used equipment.

Stands can be configured for multiple web materials and/or paths for manufacturing flexibility.

Double E stocks all non-custom parts and manufactures custom accessories (like shafts) quickly to enable unusually fast lead times on the complete package

Click here.

Click here.

Click here.

The Solution Series

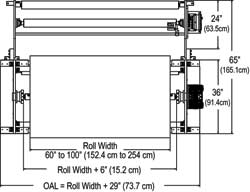

Simple Unwind Stand

Ideal when tension control is already established, and a stand is needed only to support the shaft, safety chucks, and brake.

Standard model includes A-frame, 60” - 100” web width, 40” max roll diameter, steel “Dyna–Grip” lug shaft, SP11 safety chucks, and one exit roller.

Options/Upgrades: Web guiding, “Dura–Light” carbon fibre lug shaft, 60” max roll diameter, web width < 60” or > 100”.

The Solution Series

Solution "OL" Unwind Stand

Suitable when simple monitoring of roll diameter is enough to adjust tension. It is especially economical if the web path will allow for the A-frame only (without the optional exit roller stand). Base price includes A-frame, 60” - 100” web width, 40” max roll diameter, steel “Dyna–Grip” lug shaft, SP11 safety chucks, one exit roller, and an EP.34 open loop tension control system.

Options/Upgrades: web guiding, “Dura–Light” carbon fibre lug shaft, 60” max roll diameter, web width < 60” or > 100”, exit roller stand and extra roller.

The Solution Series

Solution "CL" Unwind Stand

Delivers advanced web tension control with direct measurement and feedback from load cells. Base price includes 60” - 100” web width, 40” max roll diameter, steel “Dyna–Grip” lug shaft, SP11 safety chucks, load cell stand, 3 exit rollers, and an EP.25 closed loop tension control system with load cells.

Options/Upgrades: web guiding, “Dura–Light” carbon fibre lug shaft, 60” max roll diameter, web width < 60” or > 100”.

Unwind Stand Accessories

Double E makes it easy for you to purchase an unwind stand (or rewind stand) with the features you need. Our expert product managers work with you to specify all the right equipment - then they ensure that it's all mounted and configured to work together so you don't have to worry.

Double E makes it easy for you to purchase an unwind stand (or rewind stand) with the features you need. Our expert product managers work with you to specify all the right equipment - then they ensure that it's all mounted and configured to work together so you don't have to worry.

Core Shafts, safety chucks, brakes, and rollers. Integrated tension control systems with load cells and/or sensors, shifting actuators for roll positioning - and various other options are available as well.

Safety Chucks

Unique sliding design makes loading and unloading easy, guarantees roll security, and prevents finger jamming.

Shaft placement is effortless with square-turned-45° (standard) or patented circular jaws for high speeds.

Available sidelay adjustment for alignment and pivot table for baggy edge correction.

Core Shafts

From lightweight carbon fibre lug shafts to simple metal strip shafts, Double E offers any type of core shaft that you need.

Rollers

Low-inertia carbon fibre rollers respond to changes in web speed to minimize web scratching and stretching. Double E offers a low-cost model which can be close to the cost of a traditional aluminum roller.